The most comprehensive and accurate systems for the identification and elimination of contamination in textile industries.

Loptex, as leading manufacturer of quality monitoring systems, offers to the market suitable and sustainable solutions to contamination problems in Spinning, Nonwoven, Technical Textiles, and Recycling.

NW-Hygienic and Medical

The risk of contamination in products for medical, personal care and hygienic purposes is a fact. The final products have to guarantee purity, delicacy and comfort to the human skin.

More

NW - Automotive

Contamination is a serious threat in car interior since it affects fabric appearance and fabric performance.

More

NW - Filtration

Loptex offers sustainable and suitable solutions to contamination problems in filtration applications.

More

NW - Insulation

Contamination behaves like potential conduction spots in insulation fabrics, affecting their durability and performance.

More

Spinning

The contamination content in cottons have dramatically increased. Quality awareness of final consumers is boosting. The market requires state-of-the-art Sorting systems to face contamination in preparation lines.

More

NW - Recycling

Loptex offers valuable solutions to the sorting problem of flakes and fibers in the recycling industry.

MoreAdvantages and Solutions

Loptex stands out for its pioneering vision and innovative spirit. Loptex successfully faces the challenges and the quality demands of the market through its know-how, flexibility, experience and practical approach to problems.

End user claims reduction

Significant reduction of contamination on finished product. Production improvement on downstream process. Quality as per market demand.

Modular systems

High fibers throughput and/or high air volumes are the main critical factors that limit applications of a sorting system in Spinning and in Nonwoven preparation lines. Loptex, through modular concepts, offers successful tailor-made solutions with user-friendly software and automation.

Supply chain control

The monitoring and the supervision of raw material sub-suppliers is a strategic move in any industrial organization. Operators, through the use of Loptex digital embedded technologies, can change their business model and provide new revenues in the production chain.

Technology Platform and Systems

Loptex EXA implements arrays of embedded color camera systems at high resolution with multiple illumination sources for the accurate and comprehensive detection of contamination. Loptex EXA captures and downloads contamination images for their classification according to size and color. It offers to the market upwards fiber flow systems.

Spinning

Easy Link EXA

The Easy Link EXA upwards fibers flow is a space-saving solution to existing and new compact blow room lines. It is recommended to process high contaminated cottons. It monitors a production up to 1000 Kg/h. On demand, it monitors a production up to 1200 Kg/h.

More

Nonwovens

Easy Link EXA - NW

The Easy Link EXA-NW upwards fibers flow is a space-saving solution to existing and to new compact nonwovens blow room lines. It monitors a production up to 1000 Kg/h. On demand, it monitors productions up to 1200/2000 Kg/h.

More

Flakes and Fibers Recycling

Easy Link EXA

The Easy Link EXA upwards fibers flow is a space-saving solution to existing and new tearing lines. It is recommended to process post-industrial and post-consumer flakes and recycled fibers. It monitors a production up to 1000 Kg/h. On demand, it monitors a production up to 1200/2000 Kg/h.

More

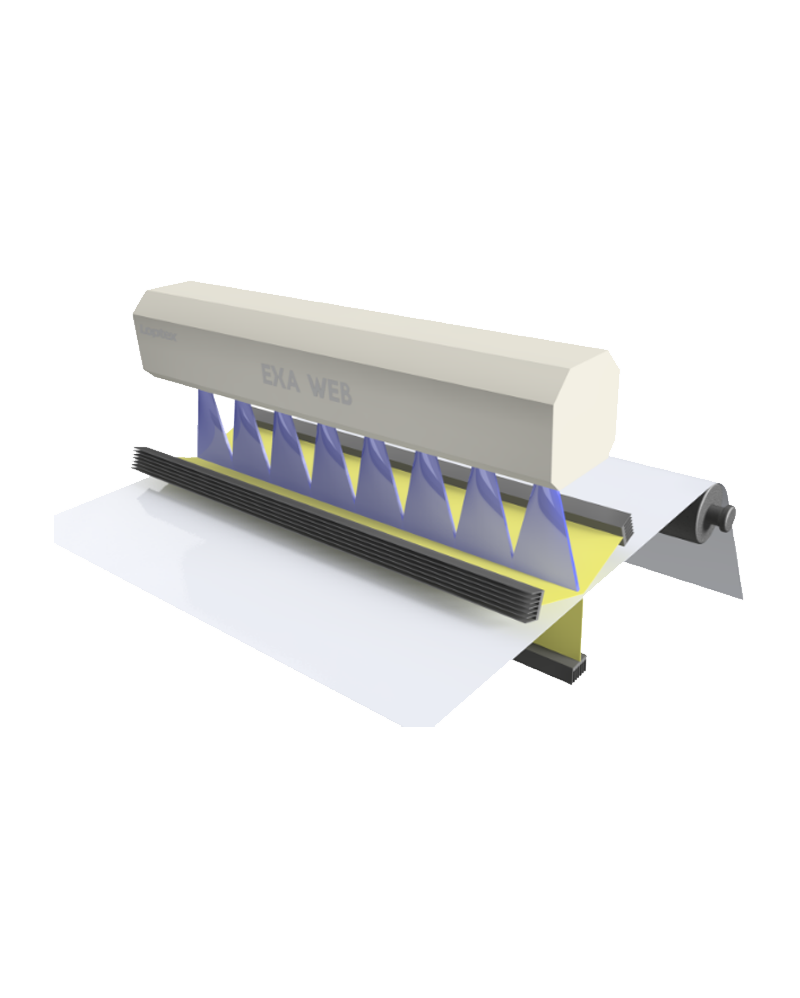

Nonwoven & Technical Textiles. EXA Webs

EXA Web identifies the remaining of contamination and defects on finished webs and provides their mapping distribution on the rolls. It is a complementary solution to the Easy Link EXA NW system installed at the beginning of the process before cards. This combined solution offers a total control of contamination and defects in Nonwovens and Technical Textiles.

MoreEXA Class

EXA Class is a Data Acquisition and Contamination Classification System. It downloads statistical data and contamination images from the Sorter units. It classifies the contamination according to color and size. Furthermore, it provides important quality information on processing material.

More

Americas, Europe and Asia

Loptex has been serving the textile industry for over 25 years. Loptex systems are installed in Spinning and in Nonwoven leading industries in the main textile areas of the world.

News/Exhibitions

ITMA ASIA + CITME

October 28th – 31th 2025

Singapore Expo

Singapore

Loptex stand: H4 D203

TEXTILE RECYCLING EXPO

June 4th – 5th 2025

Brussels Expo

Brussels, Belgium

IDEA25

April2 9th – May 1st 2025

Miami Beach Convention Center

Florida, USA

ITM 2024

June 4th – 8th 2024

Tuyap Fair and Congress Center

Istanbul, Turkey

Techtexil 2024

April 23th – 26th 2024

Frankfurt Exhibition

Frankfurt, Germany

Exintex 2024

February 27th – March 1st 2024

Centro Expositor Puebla

Puebla, Mexico

DTG 2024

February 1st – 4th 2024

International Convention City Bashundhara

Dhaka, Bangladesh